|

SPECIFICATIONS AND TIPS

|

|

|

|

FILE REQUIREMENTS - CUSTOMER PROVIDED

ARTWORK |

|

|

Some customers prefer to provide their own artwork files for their sign

projects. Sign Pro is able to work with several different PC file

formats, but there are certain formats that work better than others.

Here are some guidelines for making your files work with our design and

production systems.

FOR PROJECTS USING CUT VINYL-

We need a file in vector format (see below).

Vectors contain paths around individual components of

the graphic, enabling the plotter to cut along these paths. Overlapping

paths should be welded or trimmed so that the plotter

program will not cut through other graphic elements. Vectors print

very well on our Roland digital printer and do not require welding or

trimming. We suggest using RGB colors if possible. CMYK

colors are converted in the rasterizing process (RIP) by the software

used with the printer and color matches are not always true. If

you have specific colors you wish to match (such as Pantones), please

provide the color numbers for reference and we will attempt to match the

color as closely as possible.

paths should be welded or trimmed so that the plotter

program will not cut through other graphic elements. Vectors print

very well on our Roland digital printer and do not require welding or

trimming. We suggest using RGB colors if possible. CMYK

colors are converted in the rasterizing process (RIP) by the software

used with the printer and color matches are not always true. If

you have specific colors you wish to match (such as Pantones), please

provide the color numbers for reference and we will attempt to match the

color as closely as possible.

Preferred file formats are .ai,

.eps, .pdf or .cdr. Please note that these files support a

combination of vectors and bitmaps. Bitmaps require tracing to

produce a cut path for the plotter and that can involve significant

design time. We also suggest converting any text to curves (or

outlines). If we do not have the font, our design software will

substitute a font that may not be correct. You can also provide us

with the font information which we may be able to match.

FOR DIGITALLY PRINTED JOBS-

We can print vectors or bitmaps. Bitmaps saved at finished project

size print the best, but sometimes the file size can get very large.

We can enlarge smaller image files, but this results in pixelization

where the resulting print will look grainy or fuzzy. RGB files in

.jpg or .tif formats are preferrable and provide for very good color

matching. CMYK, Pantone and other color pallettes are not as

accurately matched in the RIP process required for printing.

Sign Pro is able to print Acrobat files (.pdf) but the

results vary depending on the content of the file. Text

enhancements, drop shadows, blends and combinations of vector and bitmap art

don't always print as intended. We are able to import Acrobat

files into our design programs which enable us to correct most issues in

the file, but it may involve some design time.

To ensure we produce the results you are expecting, please submit a smaller .jpg image file along with your original artwork so we see how the finished product

should look when completed. A preview file sized at around 1000 pixels in height and/or width is suggested.

|

|

|

VECTOR VS. BITMAP - WHAT'S THE DIFFERENCE

AND WHY IT'S IMPORTANT |

|

|

Vectors and Bitmaps are the two most widely used formats used for displaying and printing graphical images on a PC. Both

formats are used extensively in the sign and graphics industry (as well as others) with each having their own distinct characteristics and limitations.

Vectors- Vectors-

A Vector can best be compared to a dot-to-dot coloring book. By connecting a series of dots (points) in a closed pattern, you can create a shape.

For instance, a square would have four equally spaced points connected by four lines around the perimeter. When a "closed" path is created, where

there are no open spaces in the dot-to-dot connection, the interior can be

filled with a color to create a filled design.

Combining a series of shapes filled with differing colors creates an

graphic (picture). Vector pictures are commonly referred to as clip art. To create a sign using vinyl, we need the

lettering, logos or other graphics

to be in a Vector format. Computerized cutters called Plotters use an intricate knife to follow the outside perimeter of the Vector to produce the detailed

vinyl sections needed to construct a sign. Vectors can easily be resized bigger or smaller without losing quality. It is also possible to manipulate the

points of a Vector graphic to change it's appearance without distorting the overall appearance of the picture. Popular Vector-based design programs include

Adobe Illustrator and Corel Draw. The file extensions for some of the more popular Vector files are .AI, .CDR, .WMF, .CGM and .EPS (note that some of these

files may also contain bitmaps if they were included in the drawing, but in their native format these are Vector files). lettering, logos or other graphics

to be in a Vector format. Computerized cutters called Plotters use an intricate knife to follow the outside perimeter of the Vector to produce the detailed

vinyl sections needed to construct a sign. Vectors can easily be resized bigger or smaller without losing quality. It is also possible to manipulate the

points of a Vector graphic to change it's appearance without distorting the overall appearance of the picture. Popular Vector-based design programs include

Adobe Illustrator and Corel Draw. The file extensions for some of the more popular Vector files are .AI, .CDR, .WMF, .CGM and .EPS (note that some of these

files may also contain bitmaps if they were included in the drawing, but in their native format these are Vector files).

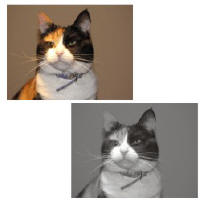

Bitmaps-

Bitmaps are best

compared to a photograph (which they generally are). To produce a Bitmap, the computer uses a series of dots (pixels) of varying colors placed side-by-side.

When there is a large enough series of dots, a visible image is produced. Increasing the number of dots will increase the size and quality of an image

(and increase the size of the resulting computer file as well). Bitmaps do not work for vinyl cut signs because there is no outside path for the cutter to follow. If we are going to use a Bitmap to produce a vinyl sign, we first have to use a trace program to convert the file to Vector. A trace program looks for

dots of a similar color and then draws an outline around the like color group.

Tracing a Bitmap can take a lot of work to "clean up" the resulting trace

file so that it will look good on the final project. Bitmaps are best

compared to a photograph (which they generally are). To produce a Bitmap, the computer uses a series of dots (pixels) of varying colors placed side-by-side.

When there is a large enough series of dots, a visible image is produced. Increasing the number of dots will increase the size and quality of an image

(and increase the size of the resulting computer file as well). Bitmaps do not work for vinyl cut signs because there is no outside path for the cutter to follow. If we are going to use a Bitmap to produce a vinyl sign, we first have to use a trace program to convert the file to Vector. A trace program looks for

dots of a similar color and then draws an outline around the like color group.

Tracing a Bitmap can take a lot of work to "clean up" the resulting trace

file so that it will look good on the final project.

With the digital imaging capabilities available at Sign Pro, we are able to print Bitmap images on vinyl

that can then be applied to various materials (Vectors can also be printed). For a quality reproduction, an original Bitmap in a high resolution is needed

(with a lot of pixels). Small Bitmaps can be stretched to a larger size, but quality is lost and the image will appear fuzzy (since enlarging only makes the

pixels larger, it does not add new pixels to the stretched image). The use of Bitmaps on signs has vastly expanded what can be included on the finished project.

No longer are you limited to varying layers of vinyl to produce a finished image. Bitmaps come in various formats as well with the most popular being .JPG,

.GIF and .PNG files (widely used on the Internet) as well as .BMP. With the digital imaging capabilities available at Sign Pro, we are able to print Bitmap images on vinyl

that can then be applied to various materials (Vectors can also be printed). For a quality reproduction, an original Bitmap in a high resolution is needed

(with a lot of pixels). Small Bitmaps can be stretched to a larger size, but quality is lost and the image will appear fuzzy (since enlarging only makes the

pixels larger, it does not add new pixels to the stretched image). The use of Bitmaps on signs has vastly expanded what can be included on the finished project.

No longer are you limited to varying layers of vinyl to produce a finished image. Bitmaps come in various formats as well with the most popular being .JPG,

.GIF and .PNG files (widely used on the Internet) as well as .BMP.

Generally speaking, Vectors are preferred for basic logos, lettering and other basic designs. Bitmaps are best for pictures, detailed drawings

or complex logos (with shading, etc.). The Sign Pro design staff can assist you in determining what formats will work best for your project.

|

|

|

VINYL INSTALLATION INSTRUCTIONS |

|

|

Suggested Installation Supplies: Tape Measurer, Glass Cleaner, Paper Towels,

Masking Tape, Application Squeegee and a Hobby or Utility Knife

Note....For

graphics covered with Transfer Paper (a liner on top of the graphic), a hard

plastic squeegee works best. For installation of graphics without

Transfer Paper, such as laminated decals, we recommend using a soft felt

squeegee to prevent scuffing of the graphic surface.

|

|

|

|

|

|

|

Clean off the area where the vinyl graphic is going to be installed using a

quality glass cleaner or solvent, removing all surface impurities. Use a paper

towel to remove residue. |

|

Position the graphic using a tape measure or a level. Use small masking tape

pieces to position the material. Place a longer piece of tape down the center

of graphic for easier application. |

|

|

|

|

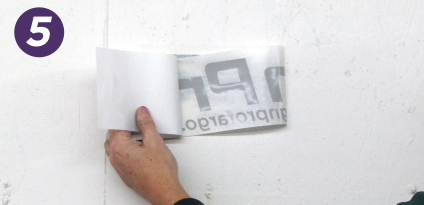

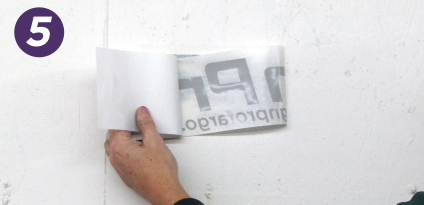

Applying the vinyl in smaller parts is easier and helps prevent wrinkles. Lift

the side to be applied, while holding the graphic away from the surface, use

the knife to cut off the backing material. Although not necessary in most

cases, a surface misting with application fluid is helpful with large

graphics.

|

|

Holding the graphic tight and slightly above the surface, use the squeegee to

apply the vinyl. Work from the center out using firm, smooth strokes across

the entire graphic.

|

|

|

|

|

Remove backing paper from other side and repeat the squeegee application

process. Make sure to work contiguously to the end. Bubbles, loose spots or

ridges may appear if areas are not squeegeed down completely.

|

|

Remove the top liner by pulling at a 45 degree angle. Water can be used on

paper-based liners to facilitate removal (if necessary). Air bubbles can be

popped using the knife point. In time, vinyl graphics tend to smooth out on

their own.

|

|

|

SIGN MATERIALS |

|

|

|

|

|

|

|

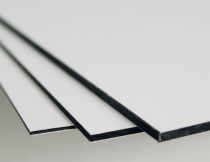

DIBOND (POLYMETAL) - Features a solid plastic core with aluminum facing on both sides. Excellent durability and lighter weight than other sign

boards. With our CNC Router, it can be custom cut into various shapes and sizes. Available in

3mm and 6mm thicknesses. Dibond comes in white, black, metallic

and colored finishes. |

|

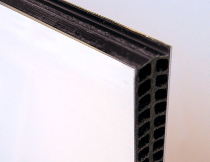

ALUMA CORE - Has a corrugated inner core with aluminum facing on both sides. A lightweight, though less

durable, alternative to Nu-Alum or Dibond. |

|

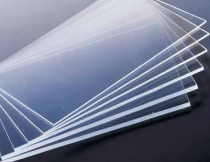

PLEXIGLAS & ACRYLICS -

Available in various

thicknesses in translucent or solid colors. Used mainly for illuminated sign faces and interior applications. |

|

FOAM CORE -

Also known as Foamboard, it has a foam core with paper faces. Used for interior signage,

primarily for short term purposes. Lightweight and inexpensive, but not very durable. |

|

|

|

|

|

|

|

|

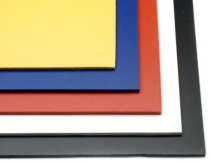

SINTRA - A flexible plastic material that comes

a variety of thicknesses and colors. Best for interior

applications, though thicker Sintra can be used outdoors. Excellent material to use for routed lettering. |

|

COROPLAST (COR-X) - Similar in appearance to cardboard but made out of plastic. Lightweight and low cost, excellent for for temporary or short-term

uses, such as yard or event signs. Available in several colors and

thicknesses. |

|

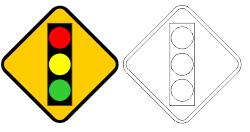

ALUMINUM/STEEL - Available in various thicknesses,

finished or unfinished. Used extensively for traffic control and

directional signage applications. |

|

WOOD - Natural or stained wood makes a rich

base for a sign or it can be router cut into custom shapes or

letters. Best used for interior applications. |

|

|

|

|

|

|

|

|

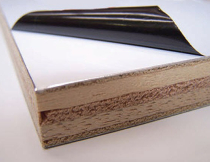

NU-ALUM - Plywood core

material with a smooth aluminum face on one or both sides.

Durable substrate that can be used outdoors if the edges are sealed

and/or capped to prevent water damage. Dibond is a popular

alternative to Nu-Alum. |

|

STYRENE - A thin, lightweight,

flexible plastic material. Primarily used for interior projects.

Excellent for displays or when mounting to a contoured surface. |

|

BANNER MATERIAL - Available

in a variety of thicknesses and finishes for indoor and outdoor

applications. With our digital printing capabilities, the

design possibilities are endless. Rollup banners for

portable display purposes are very popular. Banner material is

available in 13 or 18 ounce weights and in economy or premium

grades. |

|

MAGNETS - Rubberized

magnetic material is used primarily for removable car signs but also

works well in for any application to a metal surface where easy

removal or repositioning is desired (such as on pallet racking). |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

paths should be welded or trimmed so that the plotter

program will not cut through other graphic elements. Vectors print

very well on our Roland digital printer and do not require welding or

trimming. We suggest using RGB colors if possible. CMYK

colors are converted in the rasterizing process (RIP) by the software

used with the printer and color matches are not always true. If

you have specific colors you wish to match (such as Pantones), please

provide the color numbers for reference and we will attempt to match the

color as closely as possible.

paths should be welded or trimmed so that the plotter

program will not cut through other graphic elements. Vectors print

very well on our Roland digital printer and do not require welding or

trimming. We suggest using RGB colors if possible. CMYK

colors are converted in the rasterizing process (RIP) by the software

used with the printer and color matches are not always true. If

you have specific colors you wish to match (such as Pantones), please

provide the color numbers for reference and we will attempt to match the

color as closely as possible.